Sdkehui Raycus Fiber Laser Engraver

Sdkehui Raycus Fiber Laser Engraver

Couldn't load pickup availability

DESCRIPTION:

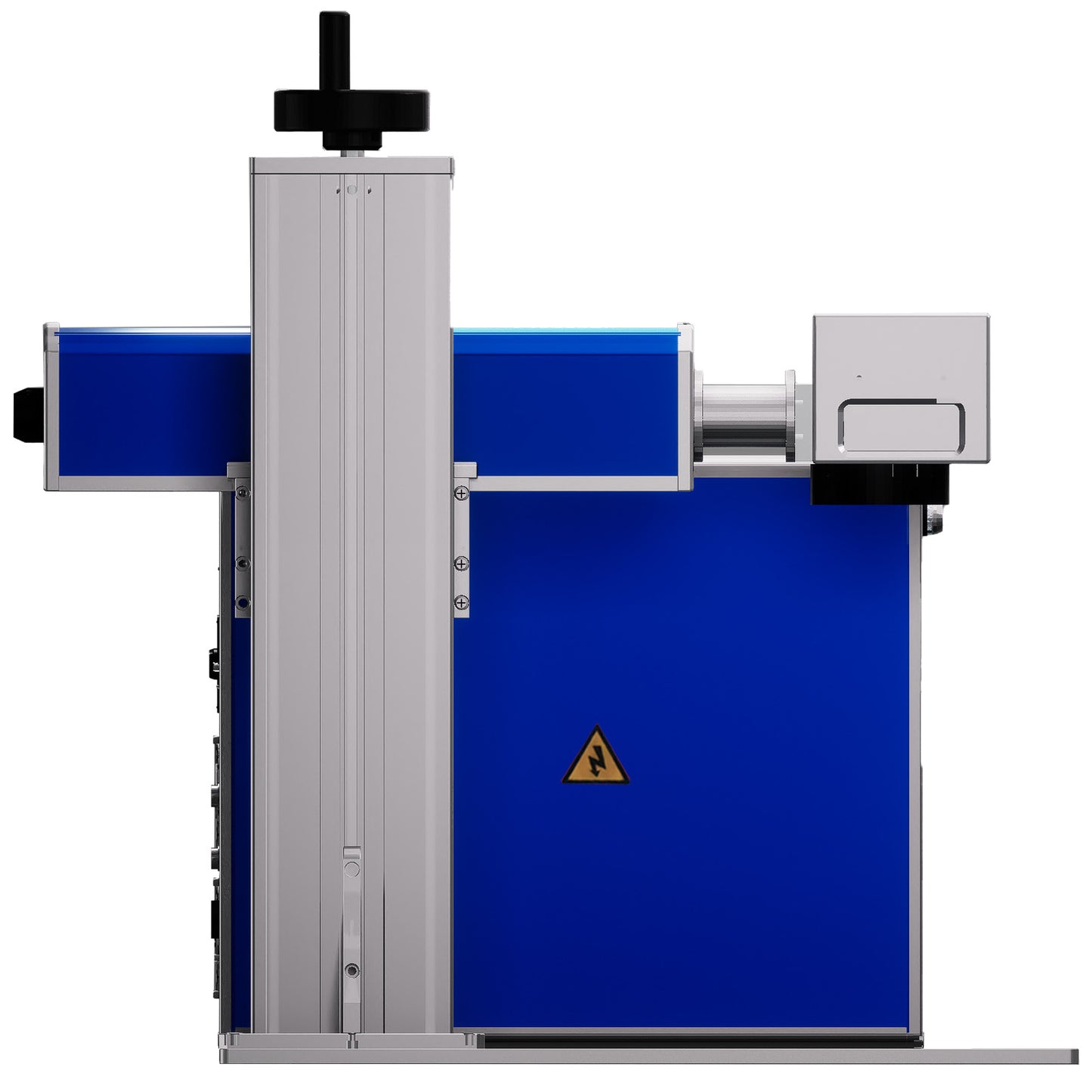

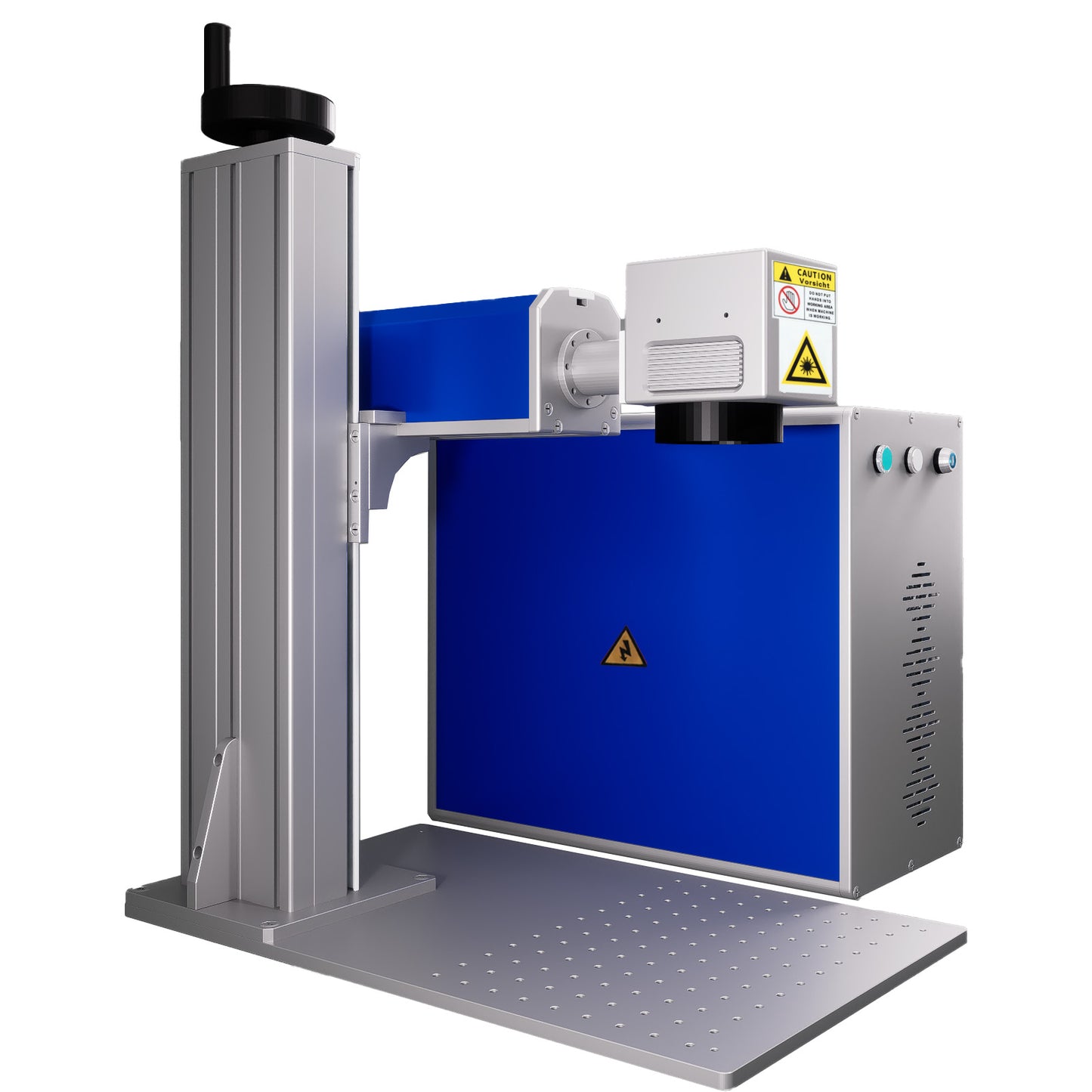

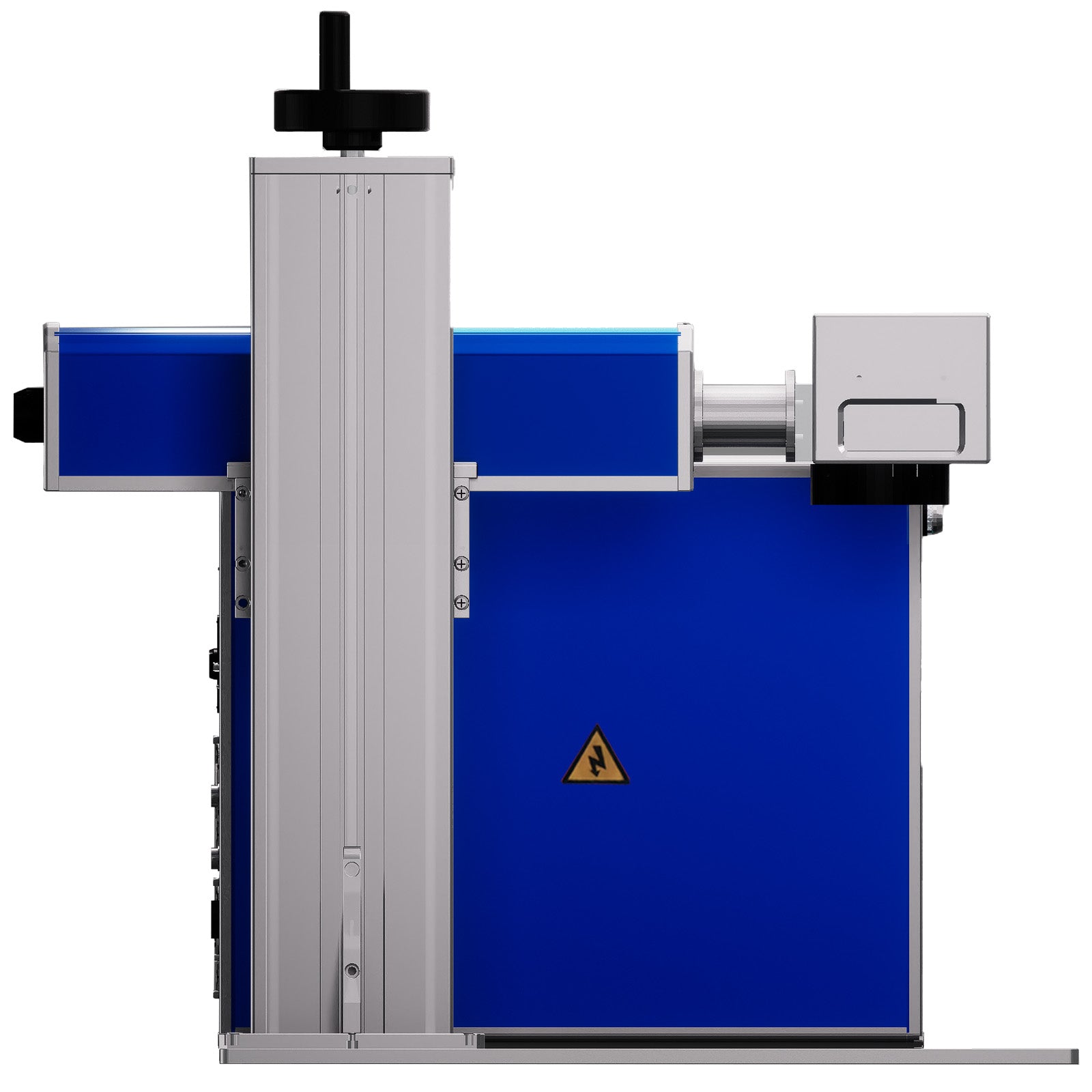

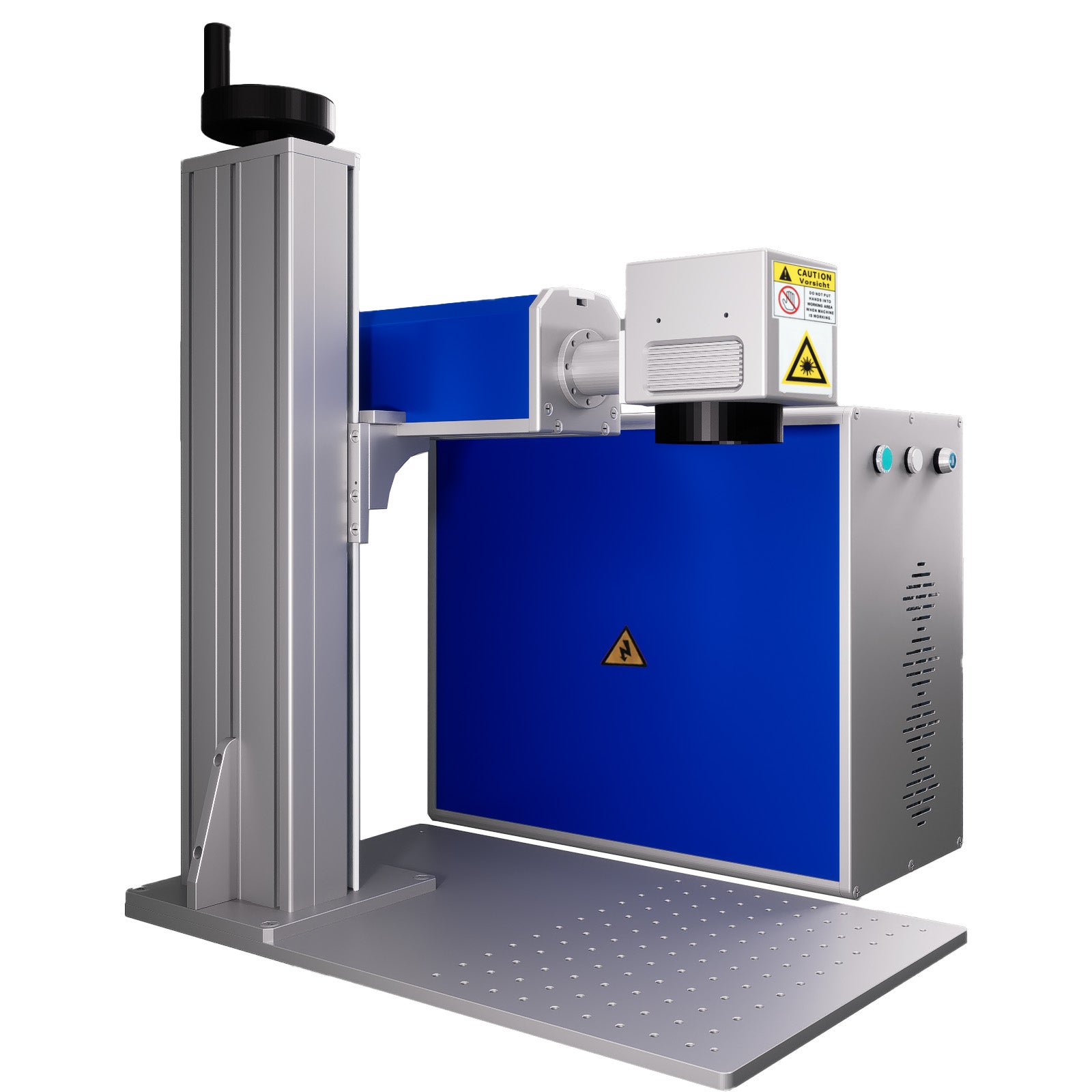

The portable fiber laser machine can mark both metal and non-metal and is characterized by its robustness, high efficiency, durability, and reliability. It is widely used for marking jewelry, cell phone keypads, auto parts, electronic components, electronic devices, communication equipment, sanitary ware, buckles, tableware, sterile equipment, hardware tools, knives, glasses, watches, stoves, stainless steel products, etc.

This fiber laser marker can be used for many different engraving projects. The improved optics include a Galyo lens for increased marking speed and high-precision engraving. The laser marking machine with the shell can better protect your eyes while working. If you do not need the shell, you can remove it manually. It comes with a ruler and field lens for the most accurate markings. The large table can accommodate a variety of products, making your next engraving easier than ever. Lift wheels can adjust the height. Foot switch improves control. Compatible with a variety of metallic and non-metallic materials, suitable for high-melting and brittle objects.

This upgraded laser marking machine with enclosure is safer and protects your eyes while working. If you don't need the enclosure, you can also remove it manually.

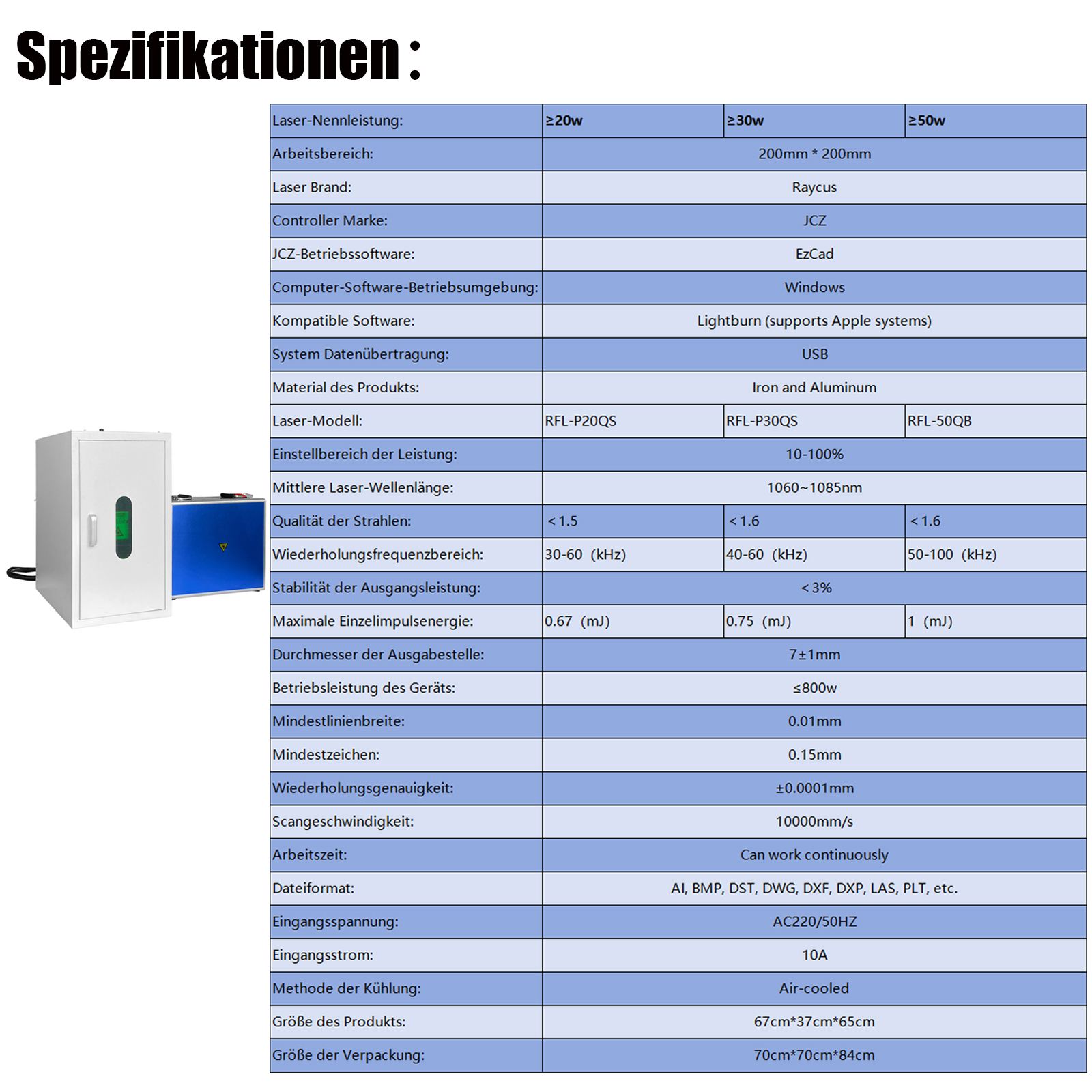

SPECIFICATIONS:

PRODUCT ADVANTAGES:

1. Fiber laser marking machine uses fiber laser with a service life of up to 100,000 hours, and its performance is better than that of the world's top-ranked machines.

2. The beam quality is high, the power is TEM00, the focus diameter is less than 20 µm, and the divergence angle is 1/4. Single-line semiconductor pump lasers are more sophisticated, especially for fine and precise markings.

3. Small, low power consumption, less than 500 W power consumption; built-in air-cooled cooling mode, heavy water cooling unit, small footprint, more convenient installation, truly energy-saving, portable.

4. High electro-optical conversion efficiency, easy to operate, no optical adjustment or maintenance, compact structure, high system integration, and low failure rate.

5. No maintenance, long service life, suitable for harsh environments.

6. Fast processing speed, 2-3 times higher than conventional marking machines, optical scanning galvanometer, high laser repetition frequency, high speed, and no distortion.

7. Application industries: Metallic materials and some non-metallic materials, electronic components, integrated circuit separation modules, electrical circuit hardware, plastic keys for auto parts, etc.

The main task of the fiber laser marking machine is:

1. Vaporizing the surface of the target material by laser energy and exposing the deep material;

2. The laser energy causes chemical and physical changes in the surface material, thereby “engraving” the desired text;

3. The material is burned by the laser energy to display the desired etching pattern and text.

The fiber laser marking machine mainly consists of a fiber laser, oscillating mirror (warhead), software control board, industrial control computer, chassis, cabinet, horizontal workbench, and so on.